One of the main priorities of a cooling fan finger guard is to protect hands from injury, and block debris without significantly affecting the airflow as well as minimising further noise. The core components are geometry, finish and build quality, which determines whether your cooling system performs as planned.

How geometry affects performance

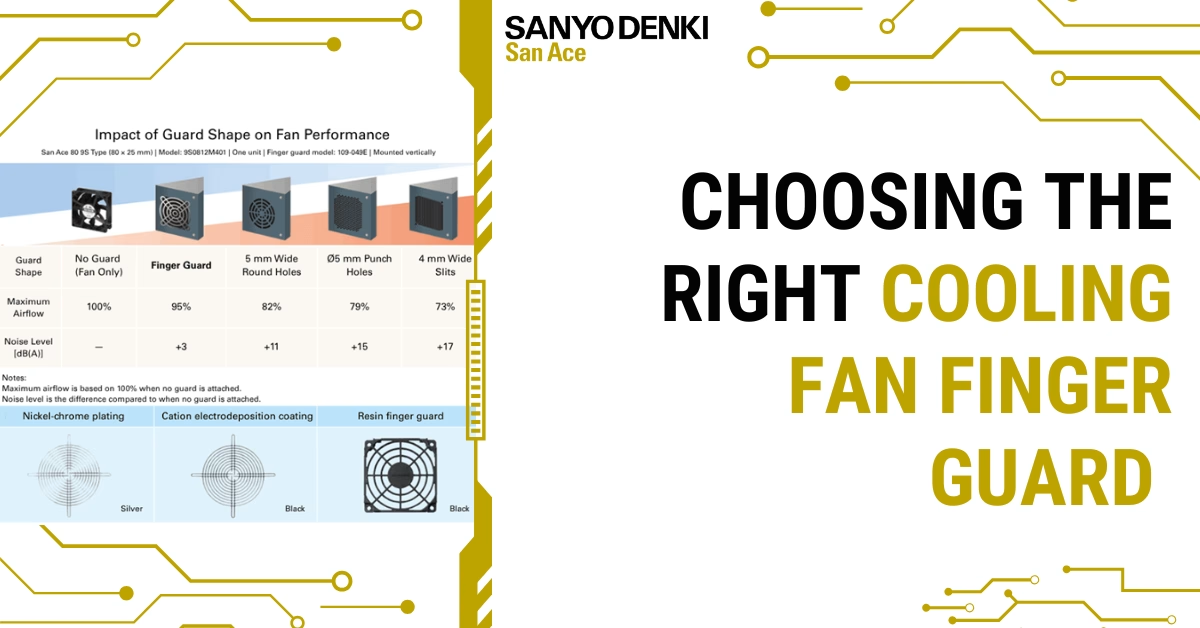

As illustrated in this diagram, smaller open areas increase flow resistance, which increases the system curve, cutting maximum airflow and creating noise at the same RPM. Wire guards keep performance at their best because they maintain a higher, free area and present smoother edges to the airstream. Punctured plates and small slits look tidy but throttle the inlet – choosing these for style or for tamper resistance will cause trade-offs that will need to be validated.

Below is a chart with a quick comparison:

As the open area drops, airflow decreases, and noise increases with the wire guarding showing the cost of this at the equivalent fan speed.

| Guard type | Open area (qual.) | Airflow impact (same RPM) | Noise impact (same RPM) | Notes |

|---|---|---|---|---|

| Wire finger guard | High | Small loss | Small rise | Best balance for electronics cooling |

| Concentric punched plate (~5 mm) | Med–Low | Noticeable loss | Medium–High rise | If used, enlarge/space holes to regain free area |

| Round-hole plate (φ5 mm) | Medium | Moderate loss | Moderate rise | Chamfer/radius edges to reduce tonal noise |

| Narrow-slit plate (~4 mm) | Low | Highest loss | Highest rise | Use only when required; validate at the target duty |

Coating options

Most finger guards have coating options, with some offering cationic electrodeposition (high corrosion resistance) as well as resin types that first best for wet or corrosive environments. If paired with certain waterproof fans, the outcome gives the best durability. Nickel-chrome plated guards can be used but are not the best choice for moisture. Here is a diagram showing the key differences of each coating for each finger guard.

EMI and Airflow Factors

Should your cooling fan finger guard hold a filter or if it sits in front of an EMI honeycomb, keep in mind that each additional layer increases airflow resistance. Take early steps in choosing the least restrictive combination that still meets your EMI needs, then confirm that the system cools and sounds as expected under normal use.

Key Takeaways

It’s best to consider the cooling fan finger guard as a flow component – maximise the open area, choose appropriate finish depending on where it’ll operate. Test the cooling system with your finger guarding choice on a bench test, this will protect hands, better represent real airflow and prevent the need for unplanned RPM increases that could cause extra noise and power use.

Find out more about our fan finger guards from Sanyo Denki and Highland, as well as Highland filters, at motorsandfans.co.uk.